- HOME

- Products

- Air treatment System

Air treatment System

Absorbent application be appropriate for dehumidification, and Keep Accurate dew point and digital automated operation. The parts of dry air is used for renewable source in order to maintain accurate dew point. Furthermore, This is high quality combined with automatic and digital operation system. The use of the best parts ensures the machine will operate with no fine fault.

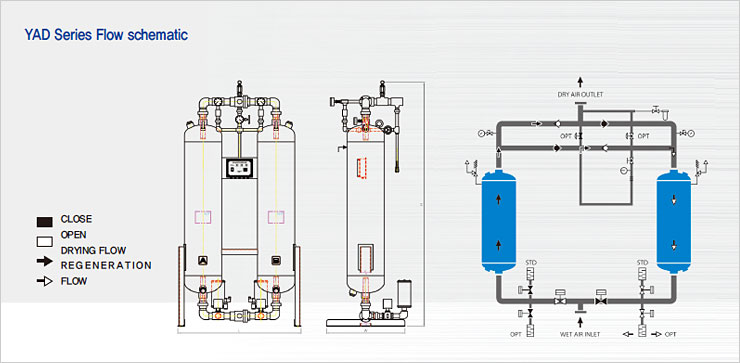

Heatless Desiccant air dryer(YAD-Series)

YAD-Series AIR DRYER is suitable performance for small and middle capacity compressed air dehumidifying. And also the structure is simple and easy to maintain without electrical control panel.

YAD-Series structure and feature

- Ensure reliable dew point

- combined with automatic and digital operation system

- Easy structure and maintenance.

- Operating cost reduction effect by dew point operation(PPD-2).

General design condition

- Inlet –air pressure : 7.0kg/㎠(STD), 10~50kg/㎠(OPN)

- Inlet –air temperature : max, 40℃

- Outlet temperature : -40℃(STD), -75℃(OPN)

- Operating cycle : 10min/cycle

YAD-Series Dehumidification and operating principles

Compressed air is discharged from the air compressor (for large 2-Way Valve) 3-Way shuttle valve with the inlet valve of the air dryer, and passing through required in flow rate and in contact time, is supplied by dew point of the dried compressed air (typically 40 ℃ ~ -70 ℃). Dehumidification and regeneration cycle is processing for 2-5 minutes, depending on the dew point. And while one adsorption tower (A) is in dehumidifying action process, outlet part of the dehumidified air in the other adsorption tower (B) is passing through the pressure reducing valve and the orifice. As a result, discharging absorbed moisture into the atmosphere. The advantage of YAD-Series AIR DRYER maximize energy savings effect can operate not only in control and regeneration air at site, but also

With a dew point control operation, depending on the condition of inlet air compression. It is also designed by sensing outlet pressure condition at alltimes

In addition, pressure drop was designed to prevent in advance.

Inlet pressure Modification factor

| Pressure (kg/cm²) | 4.2 | 5.6 | 3.6 | 7 | 8.4 | 9.1 | 9.9 | 10.5 | 11.3 | 12.7 | 14 | 15.8 | 17.6 | 19.3 | 21 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Modification factor | 0.65 | 0.83 | 0.91 | 1 | 1.16 | 1.26 | 1.33 | 1.43 | 1.52 | 1.65 | 1.88 | 2.08 | 2.27 | 2.5 | 2.7 |

TECHNICAL DATA(YAD-10~YAD-600)

| MODEL | CAPACITY | DESICCANT | CONNECTION | DIMENSION(mm) | WEIGHT | ||

|---|---|---|---|---|---|---|---|

| (Nm³/hr) | (Kg/2towers) | L | W | H | (kgs) | ||

| YAD-5 | 36 | 15 | 15A | 650 | 450 | 1,085 | 50 |

| YAD-10 | 90 | 22 | 20A | 712 | 500 | 1,710 | 93 |

| YAD-20 | 174 | 44 | 20A | 768 | 500 | 1,930 | 145 |

| YAD-30 | 246 | 70 | 25A | 834 | 600 | 1,915 | 234 |

| YAD-50 | 528 | 110 | 40A | 963 | 700 | 2,030 | 405 |

| YAD-75 | 660 | 170 | 40A | 1,066 | 750 | 2,220 | 450 |

| YAD-100 | 840 | 214 | 50A | 1,220 | 850 | 2,180 | 650 |

| YAD-150 | 1,247 | 280 | 65A | 1,460 | 850 | 2,350 | 810 |

| YAD-200 | 1,700 | 440 | 80A | 1,600 | 1,050 | 2,410 | 1,230 |

| YAD-250 | 2,100 | 530 | 80A | 1,650 | 1,100 | 2,310 | 1,300 |

| YAD-300 | 2,510 | 720 | 80A | 1,850 | 1,350 | 2,410 | 1,650 |

| YAD-400 | 3,400 | 1,000 | 100A | 2,000 | 1,500 | 2,750 | 2,000 |

| YAD-500 | 4,200 | 1,300 | 100A | 2,300 | 1,600 | 2,750 | 2,500 |

| YAD-600 | 5,100 | 1,620 | 125A | 2,500 | 1,600 | 2,860 | 3,000 |

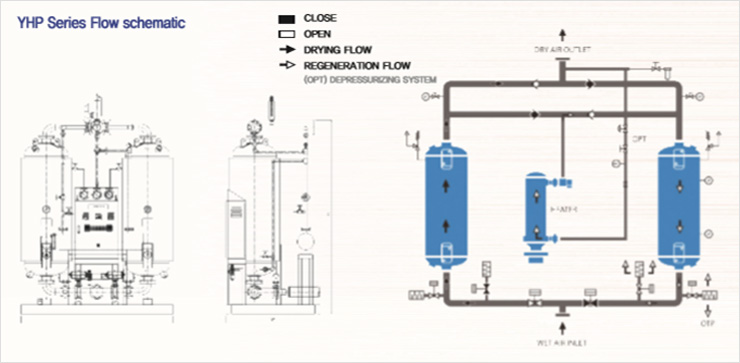

Heater External Desiccant air dryer (YHP-Series)

YHP-Series AIR DRYER is suitable performance for middle and full-sized capacity compressed air dehumidifying. And also reproduction air of a high temperature through the electric heater is supplying stable and lower dew point compressed air by absorbent.. The energy savings can be expected by various selection optional application.

YHP-Series structure and feature

- Ensure reliable dew point (-40℃~95℃)

- The latest digital driving operation (option)

- Excellent durability Belt application

- Operating cost reduction effect by dew point operation(PPD-2).

- Operating cost reduction effect by PPR-System.

General design condition

- Inlet –air pressure: 7.0kg/㎠(STD), 10~50kg/㎠(OPN)

- Inlet –air temperature: max. 40℃

- Outlet dew point temperature : -40℃(STD), -75℃(OPN)

- Operation cycle : 8hrs/cycle

YHP-Series Dehumidification and operating principles.

Compressed air is discharged from the air compressor (for large 2-Way Valve) 3-Way shuttle valve with the inlet valve of the air dryer, and passing through required in flow rate and in contact time, is supplied by dew point of the dried compressed air (typically 40 ℃ ~ -95 ℃). Dehumidification and regeneration cycle is processing for 8 hours, depending on the dew point. And while one adsorption tower (A) is in dehumidifying action process, outlet part of the dehumidified air in the other adsorption tower (B) is passing through the pressure reducing valve and the orifice and then heating by electric heater . As a result, regenerate the absorbent by removing the moisture absorbed. The advantage of YHP-Series AIR DRYER maximize energy savings effect can select control method in option, depending on the condition of inlet air compression

Inlet pressure Modification factor

| Pressure (kg/cm²) | 4.2 | 5.6 | 6.3 | 7 | 8.4 | 9.1 | 9.9 | 10.5 | 11.3 | 12.7 | 14 | 15.8 | 17.6 | 19.3 | 21 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Modification factor | 0.65 | 0.83 | 0.91 | 1 | 1.16 | 1.26 | 1.33 | 1.43 | 1.52 | 1.65 | 1.88 | 2.08 | 2.27 | 2.5 | 2.7 |

TECHNICAL DATA(YHP-30~YHP-850)

| MODEL | CAPACITY | DESICCANT | CONNECTION | E.H | DIMENSION(mm) | WEIGHT | ||

|---|---|---|---|---|---|---|---|---|

| (Nm³/hr) | (Kg/2towers) | kW | L | W | H | (kgs) | ||

| YHP-30 | 216 | 100 | 25A | 3.0 | 1,400 | 800 | 2,000 | 320 |

| YHP-50 | 520 | 130 | 40A | 3.0 | 1,550 | 900 | 1,960 | 450 |

| YHP-75 | 600 | 220 | 50A | 5.0 | 1,500 | 900 | 2,220 | 700 |

| YHP-100 | 920 | 330 | 50A | 7.5 | 1,700 | 1,050 | 2,400 | 900 |

| YHP-150 | 1,302 | 460 | 65A | 10.5 | 1,900 | 1,100 | 2,480 | 1200 |

| YHP-200 | 1,590 | 562 | 80A | 11.5 | 1,950 | 1,200 | 2,530 | 1,400 |

| YHP-250 | 1,900 | 680 | 80A | 13.5 | 2,200 | 1,200 | 2,530 | 1,600 |

| YHP-300 | 2,730 | 960 | 100A | 22.0 | 2,300 | 1,400 | 2,700 | 2,200 |

| YHP-350 | 3,120 | 1,100 | 100A | 25.0 | 2,400 | 1,450 | 2,765 | 2,400 |

| YHP-500 | 4,440 | 1,600 | 125A | 35.0 | 2,800 | 1,650 | 2,860 | 3,050 |

| YHP-600 | 5,400 | 1,900 | 150A | 40.0 | 3,000 | 1,700 | 3,030 | 5,000 |

| YHP-650 | 6,000 | 2,120 | 150A | 45.0 | 3,200 | 1,850 | 3,070 | 5,300 |

| YHP-750 | 6,800 | 2,400 | 150A | 50.0 | 3,500 | 1,900 | 3,000 | 5,600 |

| YHP-850 | 7,700 | 2,690 | 150A | 60.0 | 3,600 | 2,000 | 3,100 | 6,150 |

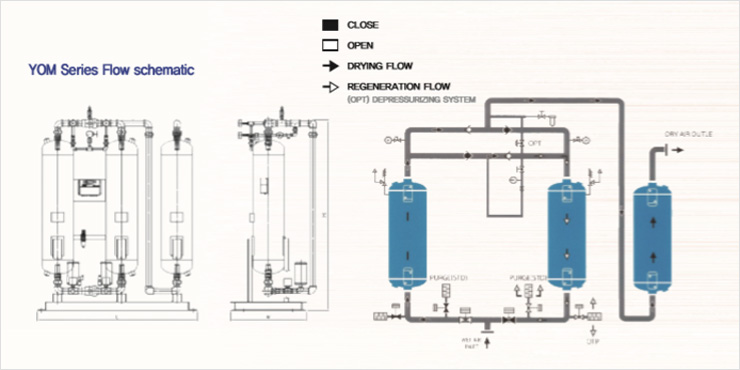

OILLESS MASTER AIR DRYER (YOM-Series)

It is possible to remove smell, moisture perfectly and can be installed regardless of Oil-lubricated, non-contained compressed air LINE.

YOM-Series structure and feature

- High Purity(100.000 times)

Compressed air through OILLESS MASTER is suitable for in the fields Drug, pharmaceutical, electronic, semiconductor, mechanical, Since clean air more then 100,000times

- Complete oil removal (0.01ppm below)

Remove or less 0.01ppmregardless of the oil content of compressed air

- Complete oil removal (removal smell)

Unpleasant smell of charred air and oil from the COMPRESSOR will be removed by specially ordered ACTIVATED ALUMINA.

- Drying dew point (Complete oil removal moisture 99.999%)

By drying moisture HEATLESS way and filling the absorbent on TOWER A.B can get a second dry air outlet dew point 40 ℃ ~ -70 ℃

- Area of Installation

There is nothing to be needed additional devices due to configure all devices and minimize area of installation on SKID.

General design condition

- Inlet –air pressure : 7Kgf/㎠(STD)

- Inlet –air temperature : 40℃BELOW(STD)

- Outlet dew point temperature: -40℃(STD), -70℃(STD)

- Operation Hour 10MIN/1Cycle

- Relative humidity: 100%

- PURGE Pressure: 3.2Kgf/㎠(STD)

- DESICCANT : SOMA(1TOWER)...(STD) / ACTIVATED ALUMINA(STD) / MOLECULAR SIEVES(OPTION)

TECHNICAL DATA(YOM-10~YOM-800)

| MODEL | CAPACITY | DESICCANT | CONNECTION | DIMENSION(mm) | WEIGHT | |||

|---|---|---|---|---|---|---|---|---|

| (Nm³/hr) | A.A | SOMA | L | W | H | (kgs) | ||

| YOM-10 | 66 | 22 | 10 | 20A | 900 | 550 | 1,660 | 130 |

| YOM-20 | 132 | 44 | 20 | 20A | 1,000 | 550 | 1,960 | 203 |

| YOM-30 | 216 | 70 | 30 | 25A | 1,200 | 700 | 2,050 | 330 |

| YOM-50 | 342 | 110 | 43 | 40A | 1,300 | 750 | 2,100 | 560 |

| YOM-75 | 690 | 210 | 70 | 50A | 1,700 | 860 | 2,300 | 880 |

| YOM-100 | 876 | 280 | 90 | 50A | 1,800 | 860 | 2,250 | 1,050 |

| YOM-150 | 1,410 | 440 | 120 | 80A | 2,200 | 1,100 | 2,300 | 1,600 |

| YOM-200 | 1,680 | 530 | 160 | 80A | 2,300 | 1,100 | 2,200 | 1,800 |

| YOM-250 | 1,920 | 600 | 200 | 80A | 2,400 | 1,250 | 2,400 | 2,000 |

| YOM-300 | 2,340 | 720 | 250 | 80A | 2,400 | 1,400 | 2,440 | 2,200 |

| YOM-400 | 3,120 | 1,000 | 320 | 80A | 2,500 | 1,500 | 2,600 | 2,600 |

| YOM-500 | 4,200 | 1,300 | 390 | 100A | 2,500 | 1,600 | 2,700 | 3,200 |

| YOM-600 | 5,100 | 1,600 | 460 | 150A | 3,100 | 1,900 | 2,700 | 3,900 |

| YOM-800 | 6,480 | 2,000 | 600 | 150A | 3,300 | 1,500 | 2,850 | 5,200 |

- 1. It could be changed by our development.

- 2. The design pressure over 0.97Mpa products is produced by the order.