- HOME

- Customer Center

- Technical Data

Technical Data

Compressor Operation

1. Check the status of the installation, plumbing and electrical circuit status before the power is turned on.

2. Check that the power supply voltage is within the nominal range of ground and (voltage range from -5% to + 10%)

Before operation

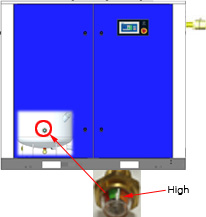

① Replenish the lubricant located on “HIGH” and the lubricant is injected into the screw compressor only

② Check STOP Lamp, after supplying power.

Caution

The lubricant is injected into compressor in order to be shipped. Check lubricant is located at the top level before initial operation after installation.

Operation

Open the discharge side of the valve, press the START button for operating the compressor

Check the direction of rotation, if you find reverse rotation, put on the emergency repair . After compressor OFF, restart by changing 2 wires of 3.

After 15 seconds, compression is to start up pressure rising.

Caution

After installing the first compressor at start, so be sure to check the motor rotation direction, the rverse rotation motor can be a great failure that will quickly damage the rotor.

Under operation

① Check the discharge pressure and the discharge temperature of the operation in the LCD monitor

② Pull the lever safety valve, and check safety valve operation.

③ Check the noise on operating.

Caution

Please do not close in front of safety valve, when on operation.

It is very dangerous that dust may enter into your eyes, When the compressed air discharge.

Stop

① Press the STOP button will automatically stop after 10 seconds no-load operation.

② Check the oil level and the oil pressure after stop