- HOME

- Products

- Compressor

Compressor

Direct-Driven Screw Compressor

15~22kW (20~30 HP)

Yujin’s mid-sized direc driven screw compressor promises the minimum operation cost

The first direct drive compressor to be developed in Korea, Micos 15D/22D utilizes motor and air end drive in 1:1 ratio instead of a speed gear. This method prevents loss of power(occurring during transmission in belt drive) and minimizes maintenance cost to reduce overall operational cost by 15%.

37~450kW (50~600 HP)

Low speed direct driven compressor becomes a leader in the efficiency race in the world.

Medium and large size oil injection screw compressor over than 50 horse power are the far-reaching range in the major industries and it is very important to select the most economical product not only the cost of compressor itself but also low operating cost as electric consumption etc,. Yujin’s direct driven screw compressor has a large 5x6 profile airend application with reduced R.P.M in order to lower the cost for operation and higher the efficiency in the ranges of 50 600 horse power compressor. MICOS screw air compressor, layout design advanced package technology adapted and high quality part application will no doubt to be the best and outrageous choice.

TECHNICAL DATA(Micos 15D~Micos 22D)

| Article | Unit | Micos 15D | Micos 22D | |

|---|---|---|---|---|

| Compression method | - | Oil flooded, 1-stage compression | ||

| Capacity (F.A.D)(1) |

7 bar | ㎥/min | 2.63 | 3.90 |

| 9bar | 2.24 | 3.34 | ||

| 12bar | 1.65 | 2.56 | ||

| Compression Unit | Driven method | - | Direct driven | |

| Suction Temperature(3) | ℃ | MAX. 40 | ||

| Outlet Temperature | MAX. Suction temperature + 15 | |||

| Cooling method | - | Air cooled | ||

| Motors | Rated power | kW | 15 | 22 |

| Input voltage | V | AC 220 / 380 / 440, 3Phase | ||

| Frequency | Hz | 50 / 60 | ||

| Starting method | - | Direct | Y-△ | |

| Pipe connection | - | 20A | 25A | |

| Control method | - | Micos-Ⅳ Micom controller | ||

| Noise level(2) | dB(A) | 65 | 66 | |

| Weight | kg | 550 | 650 | |

| Dimension (L X B X H) | mm | 1,280×820×1,348 | 1,380×880×1,348 | |

- (1) According to ISO1217 Edition3-1966, Annex-C.

- (2) According to ISO2151 Edition1-1972.

- (3) High temperature packages up to 55℃ are available

TECHNICAL DATA(Micos 37~150)

| Article | Unit | Micos 37 | Micos 55 | Micos 75 | Micos 110 | Micos 150 | |

|---|---|---|---|---|---|---|---|

| Compression method | - | Oil flooded, 1-stage compression | |||||

| Capacity (F.A.D)(1) |

7 bar | ㎥/min | 6.67 | 10.30 | 13.73 | 21.20 | 28.53 |

| 9bar | 6.11 | 9.12 | 13.10 | 18.60 | 26.16 | ||

| 12bar | 4.58 | 7.10 | 9.83 | 16.10 | 23.07 | ||

| Compression Unit | Driven method | - | Direct coupled & Variable speed drive | ||||

| Suction Temperature(3) | ℃ | MAX. 40 | |||||

| Outlet Temperature | MAX. Suction temperature + 15 | ||||||

| Cooling method | - | Air Cooled / Water cooled | |||||

| Motors | Rated power | kW | 37 | 55 | 75 | 110 | 150 |

| Input voltage | V | AC 220 / 380 / 440, 3상 | |||||

| Frequency | Hz | 50 / 60 | |||||

| Starting method | - | Y-△ | Y-△ / REACTOR / SOFT STARTER | ||||

| Pipe connection | - | 32A | 50A | 65A | |||

| Control method | - | Micos-Ⅳ Micom controller | |||||

| Noise level(2) | db(A) | 68 | 70 | 71 | 73 | 76 | |

| Weight | kg | 1,100 | 1,550 | 1,800 | 2,900 | 3,300 | |

| Dimension (L X B X H) | mm | 1,700×1,065×1,500 | 1,900x1,330x1,750 | 2,482×1,800×1,960 | 2,482×1,800×1,960 | ||

- (1) According to ISO1217 Edition3-1966, Annex-C.

- (2) According to ISO2151 Edition1-1972.

- (3) High temperature packages up to 55℃ are available

TECHNICAL DATA(Micos 190~Micos 450)

| Article | Unit | Micos 190 | Micos 225 | Micos 260 | Micos 300 | Micos 375 | Micos 450 | |

|---|---|---|---|---|---|---|---|---|

| Compression method | - | Oil flooded, 1-stage compression | ||||||

| Capacity (F.A.D)(1) |

7 bar | ㎥/min | 35.0 | 40.6 | 45.8 | 55.3 | 73.1 | 78.6 |

| 9bar | 30.0 | 33.3 | 38.2 | 50.2 | 61.3 | 72.1 | ||

| 12bar | 26.8 | 29.6 | 31.9 | 45.0 | 53.2 | 58.2 | ||

| Compression Unit | Driven method | - | Direct coupled drive | |||||

| Suction Temperature(3) | ℃ | MAX. 40 | ||||||

| Outlet Temperature | MAX. Suction temperature + 15 | |||||||

| Cooling method | - | Air Cooled / Water cooled | Water cooled | |||||

| Motors | Rated power | kW | 190 | 225 | 260 | 300 | 370 | 445 |

| Input voltage | V | AC 380 / 440, 3Phase (AC 3.3/6.6kV : Option) | ||||||

| Frequency | Hz | 50 / 60 | ||||||

| Starting method | - | Y-△ / REACTOR / SOFT STARTER | REACTOR / SOFT STARTER | |||||

| Pipe connection | - | 80A | 100A | 125A | ||||

| Control method | - | Micos-Ⅳ Micom controller | ||||||

| Noise level(2) | db(A) | 78 | 79 | 81 | 83 | 85 | 85 | |

| Weight | kg | 4,800 | 5,530 | 6,420 | 7,320 | 7,900 | 8,900 | |

| Dimension (L X B X H) | mm | 3,382×2,100×2,500 | 3,582×2,100×2,525 | |||||

- (1) According to ISO1217 Edition3-1966, Annex-C.

- (2) According to ISO2151 Edition1-1972.

- (3) High temperature packages up to 55℃ are available

Direct-Driven Screw Compressor

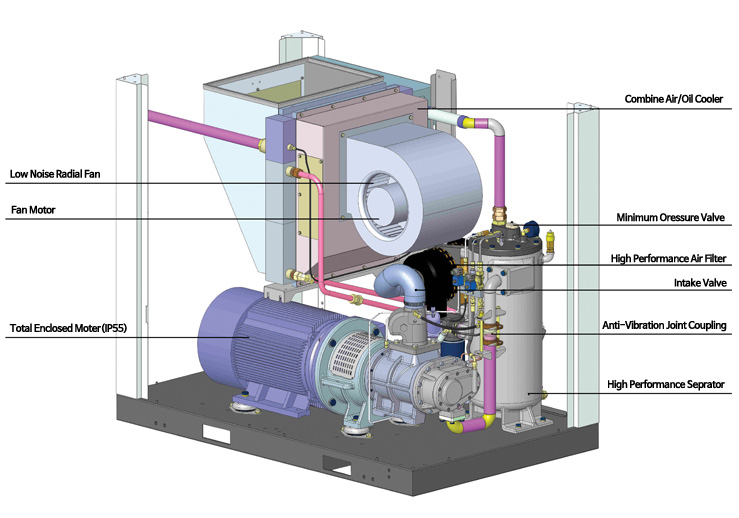

Direct Driven Screw Compressor 15~22kw(20~30 HP)

5×6 set profile air end

Exclusively developed 5×6 set profile air end presents quiet operation with high efficiency in the low speed range. .

Integrated design of air end with tank

Simplified design of compressor presents decreased number of parts possible cause of machine parts failure but also cheaper maintaining cost

Oil leakage prevention design

Reduced pipe components(Module type design) and parker fitting(international fitting manufacturer) are applied in the design to prevent oil leakage in the compressor

1:1 direct coupled drive

The 1:1 drive method connects motor with permanent coupling to prevent loss of power that occurs during belt drive transmission slip. It effectively produces large volume of compressed air with low energy consumption.

Pre-Inlet filter

Pre-filters in two side covers remove contaminant from inlet air, prolongs the lifetime of air cleaner and makes the unit clean.

Micos-Ⅳ MICOM Control system

Micos-IV Control with Touch Color LCD having trilingual interface can display a variety of function such as the operational status of the compressor, equipment protection, and maintenance message output through the appropriate icons available on the display screen, so you can operate the machine with ease and convenience.

PRE-SEPARATION construction

- Filter component layout in consideration of regular parts replacement and inspection

- Open facet and covered sides and rear

- Completely enclosed cooler duct has a side cleaning cover for customer’ safety and easy cleaning

PRE-SEPARATION construction

Pre-separation construction application of airend with high quality oil separator combination guarantees the clean compressed air less that 3PPM.

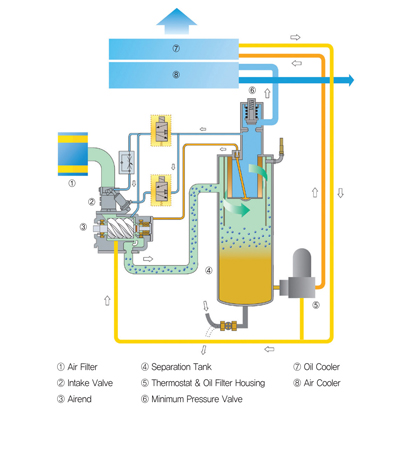

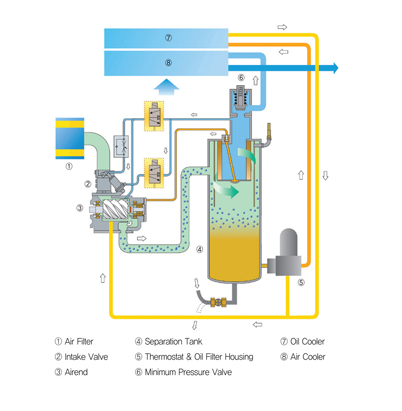

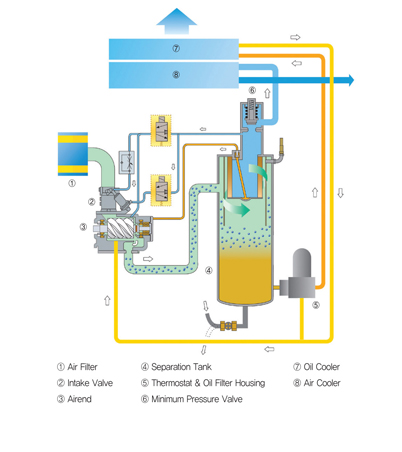

Flow Diagram

Direct-Driven Screw Compressor

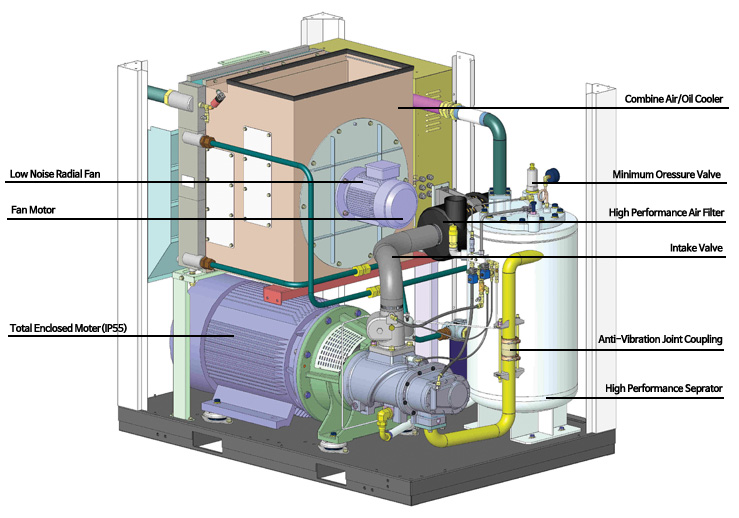

Direct Driven Screw Compressor 37kW(50HP)

Direct Driven Screw Compressor 55~75kW (75~100HP)

Direct Driven Screw Compressor 110~150kW (150~200HP)

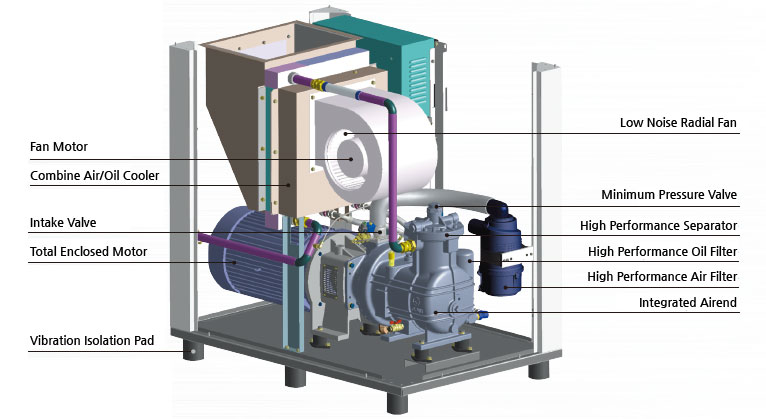

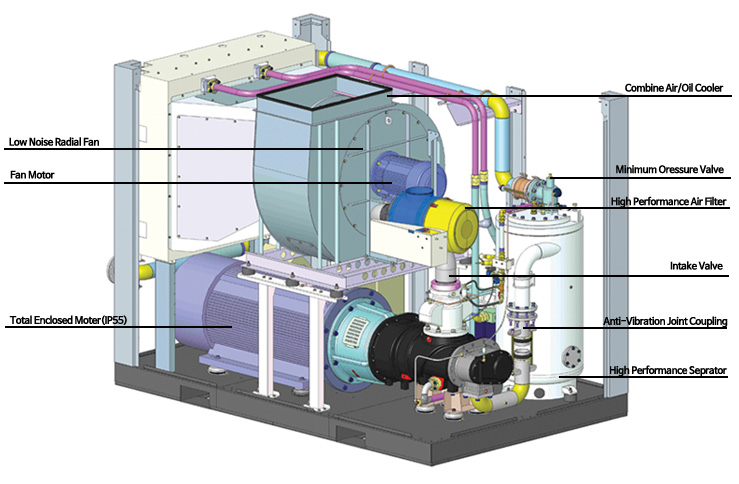

Full grinding type high efficiency air end

Solely developed and manufactured Yujin’s own air end guarantees it’s durability as well as high efficiency thanks to strict production and quality standard control.

5×6 profile air end

High tech screw air end, exclusively developed 5x6 profile produced by full grinding technology serves lowest vibration and noise level with highest efficiency which is the best and the world first class performance.

Direct drive solution

Direct drive coupling minimizes power transfer loss and the more energy saving effect will be guaranteed in case when high efficiency motor is applied.

Advanced package technology technology application

Package technology of MICOS screw compressor is developed through perfect analysis of advanced technology. From the design of suction refrigerated air to the part selection and layout design , Yujin’s compressor is developed under the application of advanced technology tends to be the best in the world.

Micos-Ⅳ MICOM Control system

Micos-IV Control with Touch Color LCD having trilingual interface can display a variety of function such as the operational status of the compressor, equipment protection, and maintenance message output through the appropriate icons available on the display screen, so you can operate the machine with ease and convenience.

Micos-IV Control with Touch Color LCD having trilingual interface can display a variety of function such as the operational status of the compressor, equipment protection, and maintenance message output through the appropriate icons available on the display screen, so you can operate the machine with ease and convenience.

Low noise and vibration design

Low speed air end with fully grinded rotors can achieve world top grade of noise and vibration performance and also guarantees long compressor lifetime.

Optimum design application for Hydraulic line and pneumatic line

Thermostats installed in oil filter housing made possible to minimize the space of hydraulic line and using internationally proven and inspected connection fitting in order to prevent any leakage problems in the circulation line. Vibration proof coupling type outlet line reacts fluently against machine vibration.

Pre-Inlet filter

Pre-filter in two side covers remove contaminant from inlet air, prolongs the lifetime of air cleaner and makes the unit clean.

Easy maintenance and low maintenance cost

- Filter component layout in consideration of regular parts replacement and inspection

- Open facet and covered sides and rear

- Completely enclosed cooler duct has a side cleaning cover for customer’ safety and easy cleaning

Direct Driven Screw Compressor 37kW (50HP)

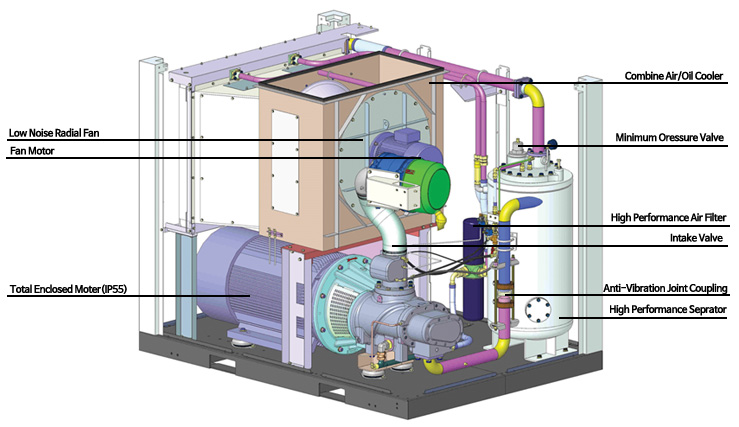

Direct Driven Screw Compressor 55~150kW (75~200HP)

Direct-Driven Screw Compressor

Direct Driven Screw Compressor 190~450kW(50~600HP)

Full grinding type high efficiency air end

Solely developed and manufactured Yujin’s own air end guarantees it’s durability as well as high efficiency thanks to strict production and quality standard control.

5×6 profile air end

High tech screw air end, exclusively developed 5x6 profile produced by full grinding technology serves lowest vibration and noise level with highest efficiency which is the best and the world first class performance.

Direct drive solution

Direct drive coupling minimizes power transfer loss and the more energy saving effect will be guaranteed in case when high efficiency motor is applied.

Advanced package technology technology application

Package technology of MICOS screw compressor is developed through perfect analysis of advanced technology. From the design of suction refrigerated air to the part selection and layout design , Yujin’s compressor is developed under the application of advanced technology tends to be the best in the world.

Micos-Ⅳ MICOM Control system

Micos-IV Control with Touch Color LCD having trilingual interface can display a variety of function such as the operational status of the compressor, equipment protection, and maintenance message output through the appropriate icons available on the display screen, so you can operate the machine with ease and convenience.

Micos-IV Control with Touch Color LCD having trilingual interface can display a variety of function such as the operational status of the compressor, equipment protection, and maintenance message output through the appropriate icons available on the display screen, so you can operate the machine with ease and convenience.

Low noise and vibration design

Low speed air end with fully grinded rotors can achieve world top grade of noise and vibration performance and also guarantees long compressor lifetime.

Optimum design application for Hydraulic line and pneumatic line

Thermostats installed in oil filter housing made possible to minimize the space of hydraulic line and using internationally proven and inspected connection fitting in order to prevent any leakage problems in the circulation line. Vibration proof coupling type outlet line reacts fluently against machine vibration.

Pre-Inlet filter

Pre-filter in two side covers remove contaminant from inlet air, prolongs the lifetime of air cleaner and makes the unit clean.

Easy maintenance and low maintenance cost

- Filter component layout in consideration of regular parts replacement and inspection

- Open facet and covered sides and rear

- Completely enclosed cooler duct has a side cleaning cover for customer’ safety and easy cleaning

Direct Driven Screw Compressor 190~450kW(50~600HP)