- HOME

- Products

- Compressor

Compressor

Belt-Driven Screw Compressor

5.5~7.5kW (7.5~10HP)

A small size MICOS Compressor offers agreeable factory environment

Micos series small compressor with YDA-3 module air end technique is designed for high energy efficiency at low operation speed, easy maintenance and low noise, So MICOS compressor can give the customer of a small and calm business factory the contentment of the maximum

11~22kW (15~30HP)

Yujin’s small and medium size belt size driven compressor proposes the new world standard

Most latest design of 5x6 profile module air end installed belt driven compressor is designed that gives the highest efficiency in the range of speed lower than 4000 rpm presents quiet and smooth operation at any industrial fields with longer machine life time. All the consumable parts are located in front of body cover so that quick replacement of consumable parts is available, module design air end and valve application enable to reduce oil line and other related parts application as simple as possible in order to cut down maintenance cost. Yujin presents a new presents a new standard line with fresh experience you will never forget

TECHNICAL DATA(Micos 5~ Micos 7)

| Article | Unit | Micos 5 | Micos 7 | |

|---|---|---|---|---|

| Compression method | Oil flooded, 1-stage compression | |||

| Capacity (F.A.D)(1) |

7 bar | ㎥/min | 0.83 | 1.18 |

| 9bar | 0.68 | 0.95 | ||

| 12bar | 0.51 | 0.73 | ||

| Compression Unit | Driven method | Belt driven | ||

| Suction Temperature | ℃ | MAX. 40 | ||

| Outlet Temperature | MAX. Suction temperature + 15 | |||

| Cooling method | Air cooled | |||

| Motors | Rated power | kW | 5.5 | 7.5 |

| Input voltage | V | AC 220 / 380 / 440, 3상 | ||

| Frequency | Hz | 50 / 60 | ||

| Starting method | Direct | |||

| Pipe connection | 20A | |||

| Control method | Loading & Unloading 제어 | |||

| Noise level | db(A) | 59 | 60 | |

| Weight | kg | 270 | 273 | |

| Dimension (L X B X H) | mm | 770 x 750 x 1,100 | ||

- (1) According to ISO1217 Edition3-1966, Annex-C

- (2) According to ISO2151 Edition1-1972

- (3) High temperature packages upto Max. 55℃

TECHNICAL DATA(Micos 11~Micos 22)

| Article | Unit | Micos 11 | Micos 15 | Micos 22 | |

|---|---|---|---|---|---|

| Compression method | Oil flooded, 1-stage compression | ||||

| Capacity (F.A.D)(1) |

7 bar | ㎥/min | 1.18 | 2.55 | 3.62 |

| 9bar | 1.50 | 2.17 | 3.13 | ||

| 12bar | 1.16 | 1.62 | 2.64 | ||

| Compression Unit |

Driven method | Belt driven | |||

| Suction Temperature(3) | ℃ | MAX. 40 | |||

| Outlet Temperature | MAX. Suction temperature + 15 | ||||

| Cooling method | Air cooled | ||||

| Motors | Rated power | kW | 11 | 15 | 22 |

| Input voltage | V | AC 220 / 380 / 440, 3상 | |||

| Frequency | Hz | 50 / 60 | |||

| Starting method | Direct | Y-△ | |||

| Pipe connection | 20A | 25A | |||

| Control method | EX-Ⅰ / Micom controller | ||||

| Noise level(2) | db(A) | 65 | 66 | 67 | |

| Weight | kg | 485 | 510 | 650 | |

| Dimension (L X B X H) | mm | 890 x 1,025 x 1,355 | |||

- (1) According to ISO1217 Edition3-1966, Annex-C.

- (2) According to ISO2151 Edition1-1972.

- (3) High temperature packages upto 55℃ are available

Belt-Driven Screw Compressor

Belt Driven Screw Compressor 5.5~7.5kW(7.5~10HP)

Belt tension adjusting device

Customer can replace belt and adjust belt tension easily with belt tension adjusting device. So it can prevent loss of compression and adiabatic efficiency according to a belt tension problem..

Yujin’s genuine parts

Yujin’s genuine parts keep the machine optimum condition.

Advanced package design

The fully integrated air end can make package layout very simple and has advantage og fail-safe operation and low maintenance cost.

Oil leakage prevention design

Reduced pipe components(Module type design) and parker fitting(international fitting manufacturer) are applied in the design to prevent oil leakage in the compressor

Flow Diagram

Belt-Driven Screw Compressor

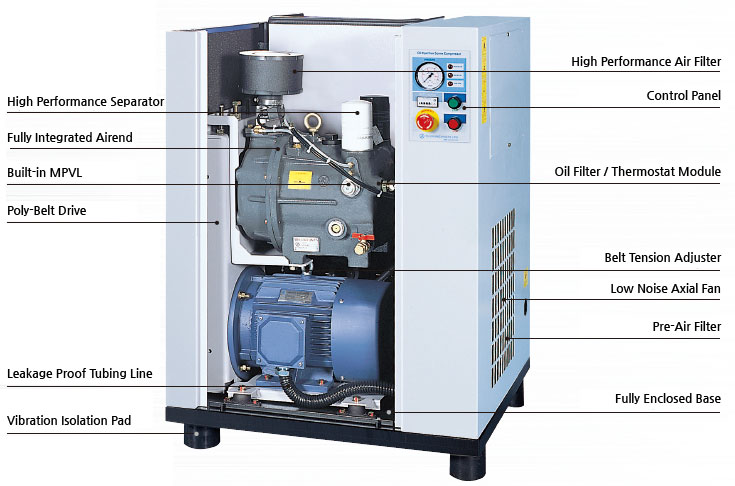

Belt Driven Screw Compressor 11~22kW(15~30HP)

5×6 set profile air end

Exclusively developed 5×6 set profile air end presents quiet operation with high efficiency in the low speed range.

Integrated design of air end with tank

Simplified design of compressor presents decreased number of parts possible cause of machine parts failure but also cheaper maintaining cost

Belt tension control device

Compress and power efficiency loss cause of tension pressure changes is eliminated and belt life time is extended by applying belt tension control device

Oil leakage prevention design

Reduced pipe components(Module type design) and parker fitting(international fitting manufacturer) are applied in the design to prevent oil leakage in the compressor

Pre-Inlet filter

Pre-filters in two side covers remove contaminant from inlet air, prolongs the lifetime of air cleaner and makes the unit clean.

EX-Ⅰ MICOM Control system

The cutting-edge EX-1 microprocessor-based control is an intelligent control that can perform various functions such as the operational status of the compressor, equipment protection, and maintenance message output through precision pressure controlling and digital input and output controlling

Air flow analysis

Input air flow definition allows high compress efficiency and minimized noise level at inlet and fan area and as a result , the compressor can be installed at any place in the production line enable for the customer to feel from the limited installation area

PRE-SEPARATION construction

Pre-separation construction application of airend with high quality oil separator combination guarantees the clean compressed air less that 3PPM.

Flow Diagram